|

Shipped since July 2019, the unit has

upgraded the transformers , can power on long term.

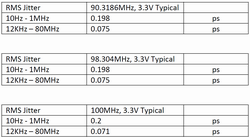

Accusilicon clocks:

Crystek clocks:

Click to download the

driver of

Amanero

combo 384

The different between R-8HE and R-8HE:

The

R-8HE has apply the same regenerative power supply and R-2R

modules of R-7HE for guarantee the sound quality quite close to

the R-7HE , the sound has high define transparency, high dynamic and

clean detail but at the same time , the sounding still quite analog.

The R-8HE has apply some high

performance SMD parts (the transistors still apply foot pin parts )

and auto produce machines to build the board so can reduce the cost

and sell lower price , let more customers can afford the

regenerative power supply built in product, if the other devices in

the system have enough revealing, you can experience the huge

improve on sound quality because the regenerative power supply built

in .

About the

regenerative power supply built in product:

It is said the boss of a well known brand company that is built high

end audio products answer the question of why they don't build the

products with built in regenerative products? He said this will

increase the price to 3x times. And less customers can afford.

I am agree that . Based

on their price policy is relative to the sound quality, a good

regenerative power supply built in can boost the price to 3x times.

But our price policy is

relative to the parts cost, so even though we have apply the most

expensive full analog design regenerative power supply and larger

chassis and much lot parts, the price

just increase around 50% .

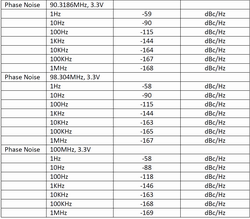

Pure analogous

Regenerative power supply :

The regenerative power supply like a

proprietary electric generator built in the unit.

It can block most

disturb from the power line , supply the ultra clean power supply for

the audio amps , reproduce the most neutral and analog sound

like audio signal for the system and the users.

In the

regenerative power supply design, the AC power through the

regenerative input transformer

, conversion to DC power ,through the class A PSUs power supply

for the regenerative wave generator and driver stages .

A balance regenerative regular wave

generator produce the ultra low distortion 50Hz wave ,through the

balance gain amps and the strong output stages ,

drive the regenerative transformers produce the clean AC power

supply feed to the separate class A PSUs power supply for the L and R

channel preamps .

The class A

parallel connection PSU has very high input impedance to avoid

disturb through the PSU from affecting the signal parts and low

output impedance with very fast speed and high linear, it

is a very clean power supply.

Audio-gd

on the regenerative power supply design points :

1, Through analyzed the AP SYS-2722 ,do a lot practises ,test and

listen , full analog design of the regular wave generator have much

lower distortion than the digital generator.

2, Digital drive stages have higher efficiency , but full analog

drive stages have much better analog sound like .

3, 400Hz regenerative wave have higher efficiency , 50Hz

regenerative wave had much far away the human ears sensitivity

area than the 400Hz, boost the sound have much better analog

sound like.

Pros and cons of R-2R

DAC :

Advantages:

1.R-2R will not convert the

clock signal into the output signal.

2. R-2R is not sensitive to

jitter while Delta-Sigma DA is much more sensitive to jitter.

3. The output signal is much

more precise compared to Delta-Sigma DA .

Weaknesses:

1.THD today is extremely good with

Sigma Delta chips; R2R ladders are good too but not as good.

2. Glitches and accuracy of the

ladder resistors are very difficult to avoid and require complex

technology to resolve it.

R-2R basic design in the

market:

The R-2R DAC

is very popular nowadays and available from DIY kits and completely

up to of the shelf high-end products.

In the low range DIY

market, the R-2R design is often based on old technology designed a

long time ago by MSB and only includes basic R2R ladder design and

do not include the wonderful correction design of the original MSB

technology. This design uses data shift registers logic chips in

series mode to convert the data to an analog signal. The structural

R2R technology issues cannot be avoided, and performance is solely

depending on the accuracy of the ladder resistors.

In the High-End of the shelf (finished products)

market, the R2R design is much more complex only to reach best

performance. A basic R2R ladder is simply not sufficient enough to

achieve good performance and sound quality! Some manufacturers are

using shift registers design. A less complex and less performing

design based on traditional logic chips working in serial mode to

correct the ladder.

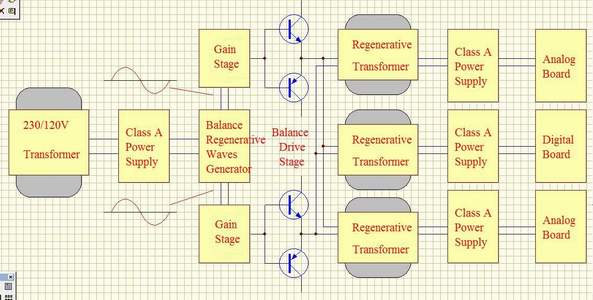

A far better design switches

resistors in parallel mode. An ultra-fast FPGA controls and corrects

the R2R ladder. The parallel design mode controls every bit

respectively and therefore achieve unprecedented performance. (In

parallel mode only 1 clock cycle is needed to output all data;

serial design mode needs at minimum 8 up to 24 clock cycles) The

parallel design is much more complicated. Once designed properly it

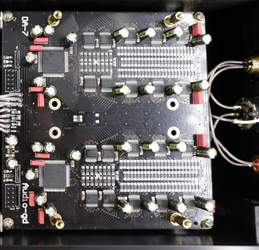

can correct every bit of the ladder. Photo below shows a

design with such FPGA, can correct the unavoidable

imperfections of the R2R ladder caused by tolerance of resistors,

glitches to achieve best performance.

Accuracy of the ladder resistors

(tolerance):

Many people believe the tolerance of

the resistors in the ladder is most important to reach best

performance. Nowadays 24 bit resolution is standard. What tolerance

is needed to achieve 24 bit resolution?

When we look

at 16 bit the tolerance of 1/66536, 0.1% (1/1000) is far not enough,

even a tolerance of 0.01% (1/10000), the best tolerance available in

the world today, still cannot handle 16 bit request correctly; we

are not even calculating 24 bit here!

The tolerance of

the resistor will never solve Imperfections of a ladder. This would

require resistors with a tolerance of 0.00001% and can handle 24 bit

resolution. This is only in theory because the discreteness of the

switch logic chips have already too much internal impedance and will

destroy the impossible tolerance of a resistor.

The solution

is to correct the ladder and not only depend on the tolerance of

resistors. Itกฆs a combination of both: Ultra-low tolerance resistors

controlled by a correction technology using very high speed FPGA are

applicable in in our design.

Importunacy of the FPGA in the R-8HE:

FPGA stands for Programmable Array Logic.

Nowadays the

FPGA is applied in a lot high end grade DACs; like the popular

ROCKNA WAVEDREAM DAC.

The internal

hardware design is fully controlled by complex software. A huge

advantage is the fact the software in the FPGA can easily be

upgraded offering new features or improve the performance. Such

design is much flexible and future proof!

FPGA tasks in the

R-8HE

The FPGA in the R-8HE is responsible for:

1. High performance

SPDIF interface, replacing traditional less good performing SPDIF

interface chips like DIR9001, WM8805 or AK411X,etc.

2. Full re-clocking

process with FIFO design applicable on all inputs. This way the

output data keeps fully synchronized with the clock signal to reject

any jitter.

3. Built in 2X, 4X

and 8X oversampling and digital filters and on top of this 4

different true NOS (only analog 6dB filtering) modes. To completely

configure it to your liking!

Fully discrete output stages

The

signal last stage is the analog output stages, they can much effect

the whole DAC sound quality.

After d/a conversion by

the R2R D/A modules the analogue signal is transported by fully

discrete matched-transistor output stages.

The high speed special ACSS output stages are non-feedback and

current driven design.

Special because almost

all other designs need to convert the signal multiple times from and

to current or voltage, resulting in less detail and less good

staging.

The output buffers are

single ended FET. Two stages in parallel to reach very low output

impedance. All output stages are in pure class A design without any

(negative) feedback to achieve purest and a real live sound

reproduction.

The 4 OPA opampกฆs are

functioning as DC servo, this way no coupling-capacitors are needed

and DC output is automatically biased! Resulting in a perfectly

neutral sound.

There are no relays or

other switches in the signal path after DA modules to perform the

best and purest sound quality.

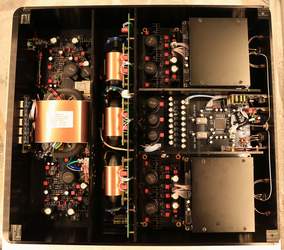

Heavy power supplies design:

Uses four R-core transformers (In total

255W ) and more than 60,000uf audio grade NOVER capacitors are used

to ensure ample and smooth power delivery.

6 groups discrete class A PSUs power supply for the regenerative

drivers and the analog audio signal parts. And there are 10 groups

ultra linear PSUs for power supply for the digital parts .

This results

in ultra-high speed and ultra-low noise performance. Clean and

independent power for all different parts to achieve highest

quality.

Finishing touch:

The R-8HE has completely separated power supplies .Digital, left and

right analog channel have their own dedicated transformer. The

signal

board and transformer compartment are separated by 5mm thick

aluminum plates for high isolation degree.

It improves the signal-to-noise ratio, isolate the harmonic

interference and reduce noise, which will make the sonic background

cleaner and blacker.

The Left and Right analog parts are placed symmetric beside the

digital board to keep the wires and distance identical to ensure

equal output performance on both channels .

The R2R DA modules are assembled between two aluminum boards to

avoid any RF interferences.

ก@ |